The tracking of a product consists of registering all the actions, processes and places where the product has already passed and it also can be identified individually from its place of origin to its final destination. Thanks to the tracking, we know what its place of origin was, the historical of processes and transformations that the product has suffered, what its final destination was and what its distribution chain has been between the different places through which it has been able to pass.

The tracking has converted into an essential procedure in several industry areas because of its importance and obligatory nature in fields such as processed food, phytosanitary and pharmacy.

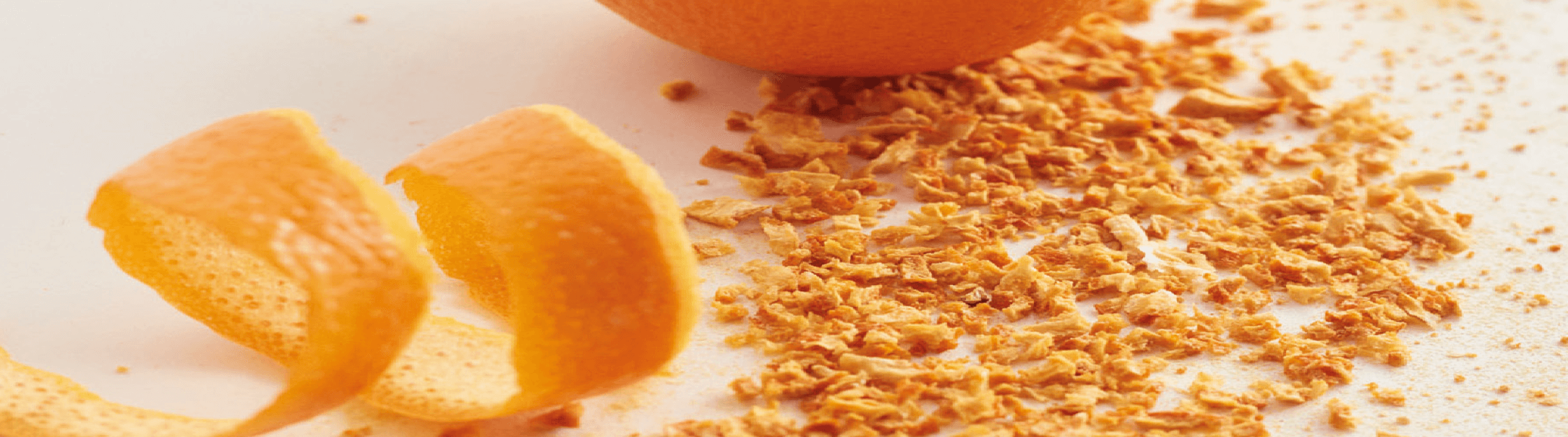

One of the most important principle in Vegenat is the tracking. We control each and every step of our value chain: from the seed production to the product delivery (onions, citric products, olives and dehydrated anchovy) in the installations of our clients.

For that, Vegenat relies on a technical and high experience team who makes a full monitoring of the crops within an integral management work. In that way, we have access to the situation of every dehydrated product in real time.

What are the benefits of implanting a tracking system?:

1- Improve the quality of processes.

Having a tracking system involve a better documentation about the processes and actions the product goes through, and therefore, make easier the stoppage, the control and the action in case of finding problems with a determinate product or intern incidents in work procedures.

2 – Cost reduction.

Having more information about every process our product goes, it is possible to detect mistakes in our work methodology with more promptly and even improve intern processes, consequently, we will have a cost reduction.

3 – Time saving.

Every time we have to recover information about a batch, through a single click, we can obtain all the information about that batch in an accurate way, what is more, who the supplier is, to which clients we have sold it to or in which production we have elaborated or consumed it.

4- Guarantee of quality.

In the tracking system, the label of Vegenat’s products with its cod of batch is essential for our suppliers as well as for our clients. They will trust more in us once they see all the products have been labelled. In addition, all the sectors with a obligatory nature contribute to the certification of the product.

5 – Finding the origin of the problem.

This point has a special importance considering that allow us to demonstrate our innocence in case of a contamination from one of our dehydrated products. Knowing the batch which causes the problem and implementing a tracking backwards, we will obtain quickly all the information connected to the batch, the origin of the raw materials which have been used and the supplier who provided to us.

6 – Identify to which client we send each batch.

In the same way we can find the origin of the problem when we detect a problem in one of our products; making use of the tracking permit us knowing to who has been distributed and where. In case of any problem, we will have it enclosed.

7 – Information is power.

We know information is power and every information sent by the tracking system is useful for making business decisions and improve our procedures.

8 – Improving communication skills.

For those companies that manage the procedures and transformation of products, the tracking system will help them in the coordination and communication of their different sectors which take place in the production process.

This is why tracking is not just an exigency, but a value inside the company which gives not only good products, but also a safety commitment and transparency to our clients.

Thus, in Vegenat, in order for Food Defense system to be efficient, products such as dehydrated onions or citric products are controlled, managed and evaluated with the purpose of protect the health of our clients.

The R+D department review new or enhanced technologies to apply to productive processes in order to obtain dehydrated products with a better quality. They add value to our customers making an effort to investigate and develop processes under technical and agronomic methods respectful with the environment.